- TOP

- Product information

- PULP&PAPER CHEMICALS

- MEIKASURF

MEIKASURF

Dispersant for hydrophobic fibers

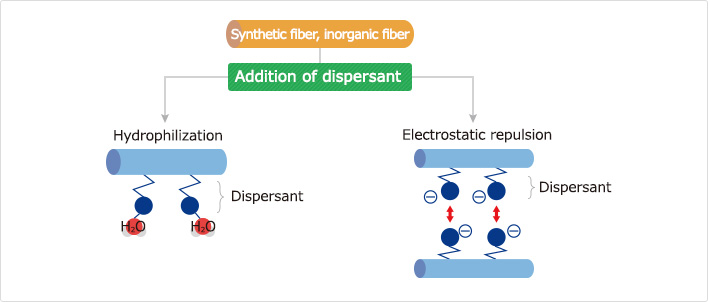

Various synthetic fibers and inorganic fiber have a problem of making paper in wet method since those fiber surfaces are hydrophobic and not familiar with water and then occurs coagulation of each fiber and foaming.

It is able to obtain good formed sheet without binding fibers by pre-treating by dispersants which make fibers be friendly with water and induces the repulsion of each fiber.

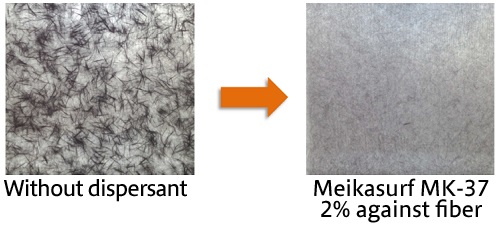

Test example 1 The method of judgement of the condition of dispersion in water.

- Dispersing PPS(Polyphenylenesulfide)fibers

Appearance for each recipe after mixing PPS fibers with dispersant.

| Recipe | 1(blank) | 2 | |

|---|---|---|---|

|

MEIKASURF MK-37 |

% against fiber |

1.0 | |

| After stirring for 1 min |

|

|

|

The sample added dispersant shows good dispersed condition and blank sample shows quickly floating of fibers instead.

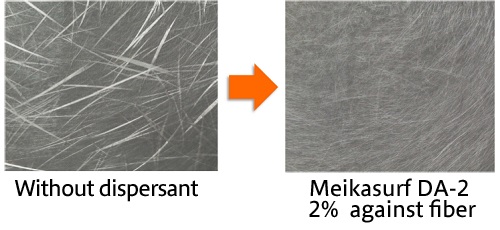

Test example 2 The sheet formation

Case 1 Glass fiber

Product line up

|

Dispersant \ Fiber |

MEIKASURF BP-25 |

MEIKASURF DA-2 |

MEIKASURF MK-37 |

PASCOL HA-52 |

PULSET HA |

LACCOL AL |

|---|---|---|---|---|---|---|

|

Polyethylene |

|

○ |

||||

|

Polypropylene |

|

○ |

||||

|

Polyethylene |

|

○ |

||||

|

Polyphenylene |

|

○ |

||||

|

Rayon |

|

○ | ||||

|

Aramid |

○ |

○ |

○ |

|||

|

Carbon |

○ |

|

○ |

○ |

○ |

|

|

Glass |

|

○ |

○ |

○ |

||

|

Ceramic |

○ |